Liquid coating is one of the most important processes in the surface coating industry. This versatile method not only provides protection, but also adds a high quality aesthetic finish to a wide variety of surfaces, such as metal, plastic and wood. In this article, we will review the key benefits of liquid paint and explain why it is the preferred choice for many industrial painting projects.

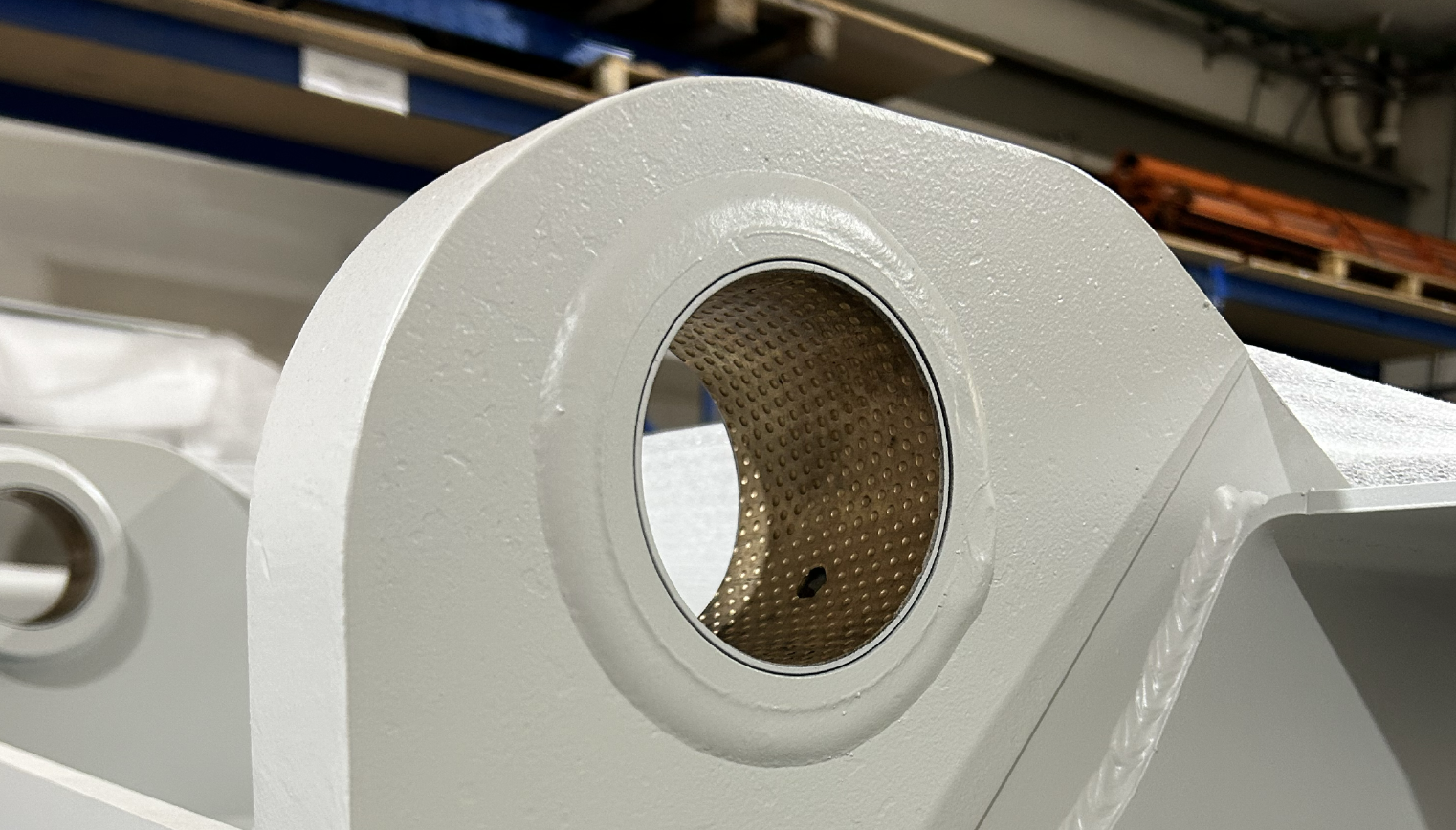

Applying liquid paint makes it possible to cover different types of surfaces with a protective and decorative coating that meets multiple needs. This process is designed to provide a uniform and resistant paint layer that protects surfaces from factors such as corrosion, UV rays and wear. What’s more, it enables precise finishes on complex surfaces and parts with incredible details.

Thanks to its versatility, liquid paint can be adapted to almost any surface and is available in a wide range of colours and finishes, making it ideal for both aesthetic and functional purposes. Compared to other coating methods, liquid paint offers several advantages, including the following:

- High-precision finishes

The liquid coating process allows for a uniform finish without any visible imperfections. In addition, intermediate processes such as puttying and polishing can be carried out to correct any defects before final application, ensuring a high precision and quality result on the treated surface.

- Adaptability to complex shapes and materials with special needs

Unlike other coating techniques, liquid painting allows adjustments to be made during the process. It can be applied at lower temperatures, which is particularly advantageous for certain heat-sensitive materials such as plastic and wood. In addition, its ability to adapt to irregular shapes and complex surfaces makes it a flexible and highly adaptable solution on the production line.

- Protection and aesthetics in a single coat

Liquid paint not only ensures long-lasting protection from environmental and wear factors, but also provides a superior aesthetic finish, making it a complete coating solution. This technique is essential for those seeking the ideal combination of protection and appearance for their industrial projects.

In conclusion, liquid coating is an essential technique for achieving versatile, precise and durable coatings on industrial surfaces. Its adaptability to different sectors and its ability to meet the highest quality standards make it a reliable choice for those seeking advanced coating solutions. If your project requires a solution that combines protection and aesthetics, liquid paint is definitely a safe bet.