In the field of industrial painting, attention is often focused on the type of coating, its resistance, or the final finish. However, there is a decisive factor that determines the performance and durability of any painting system: surface preparation.

At Mestres Pintura Industrial, we are clear about this: a good industrial paint job does not begin with the application of paint, but much earlier—with the analysis of the substrate and the prior treatments that ensure proper adhesion and long-term protection.

Surface Preparation: the foundation of any industrial painting system

The main function of an industrial coating is to protect surfaces against corrosion, abrasion, chemical agents, or the most demanding environmental conditions. For this protection to be effective and long-lasting, the paint must adhere correctly to the substrate.

When a surface shows rust, grease, dust, moisture, or poorly adhered remnants of old paint, the painting system loses effectiveness from the very beginning. In such cases, even the best coating cannot compensate for a poorly prepared surface.

That is why surface preparation is not just a preliminary step, but a structural element within the industrial painting process.

What happens when surface preparation is inadequate?

Poor surface preparation usually leads to visible problems in the short or medium term, directly affecting the durability of the coating. The most common failures include:

-

Paint peeling or flaking

-

Formation of blisters or bubbles

-

Corrosion under the coating

-

Premature loss of protection

-

Need for repainting earlier than expected

In most cases, these issues are not related to the quality of the paint itself, but to insufficient or incorrect surface preparation.

Coating adhesion starts at the surface

Adhesion is one of the key factors in any industrial painting process. To ensure it, the surface must meet two fundamental conditions:

1. Clean, contaminant-free surface

Oils, greases, salts, or dust act as a barrier between the paint and the substrate, preventing proper bonding of the coating.

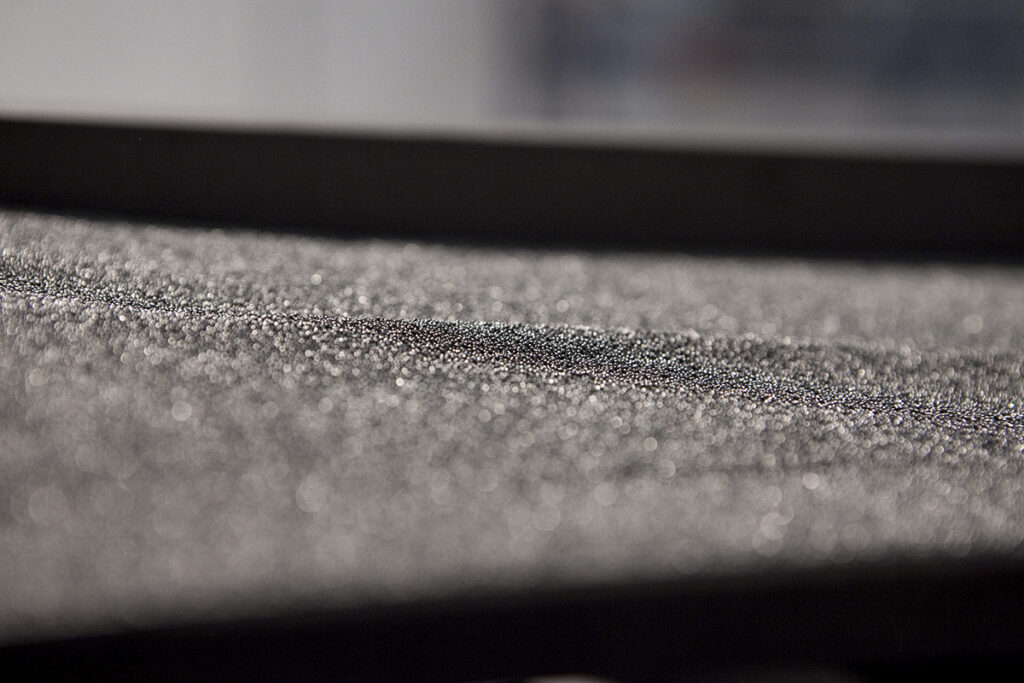

2. Appropriate surface roughness

Especially on metal surfaces, it is essential to create an anchoring profile that allows the coating to adhere uniformly and remain stable over time.

This is where surface treatment processes play a crucial role.

Surface preparation methods in industrial painting

The preparation method is defined according to the material, the initial condition of the surface, and the coating system to be applied. The most common industrial painting processes include:

Cleaning and degreasing

An essential step to remove surface contaminants before any other treatment.

Mechanical cleaning

Processes such as brushing or sanding remove surface rust or poorly adhered paint residues, especially in maintenance work.

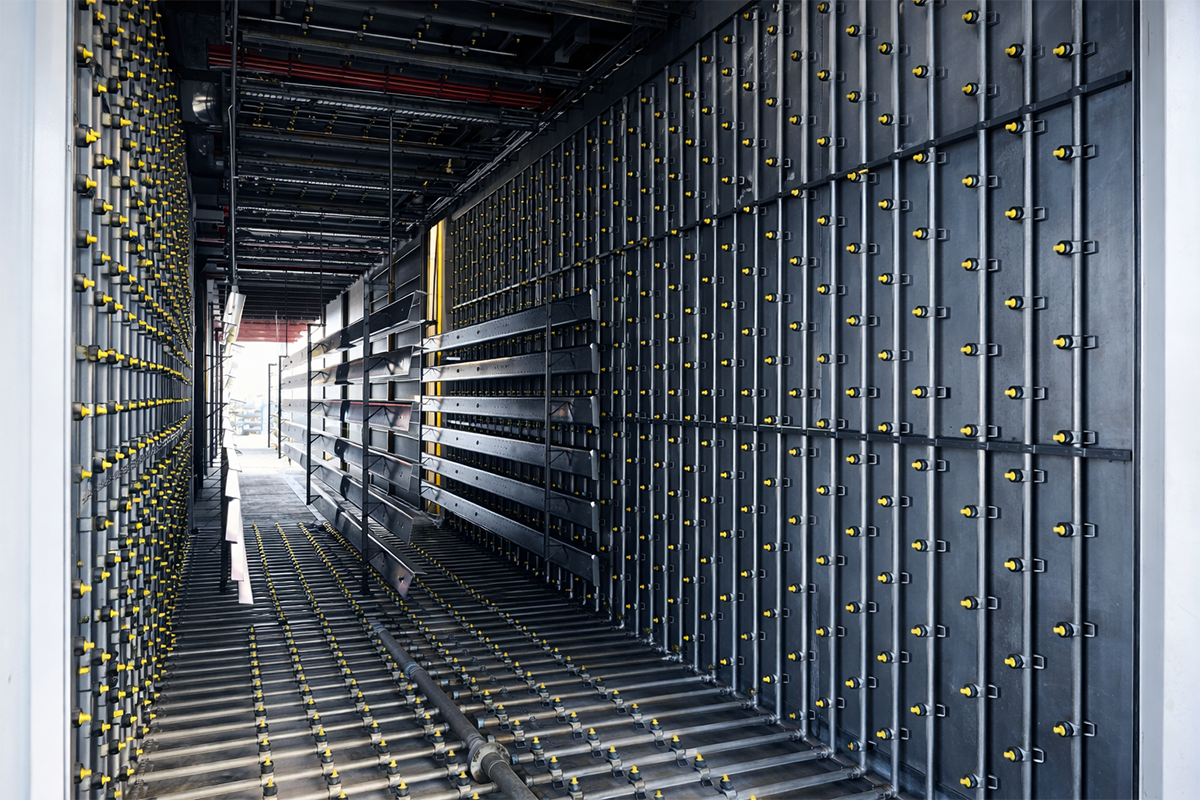

Shot blasting

Shot blasting is one of the most effective and widely used methods in industrial painting because it:

-

Completely removes rust, mill scale, and contaminants

-

Creates a uniform and controlled surface roughness

-

Significantly improves coating adhesion

A properly blasted surface is the ideal base for high-performance anticorrosive systems.

Surface preparation and standards: A key aspect of Industrial Painting

Surface preparation is not an arbitrary process. Technical standards define the required levels of cleanliness and preparation according to the type of project and the level of protection needed.

Compliance with these standards ensures that:

-

The coating system performs as designed

-

The expected durability levels are achieved

-

Future problems and unnecessary extra costs are avoided

At Mestres Pintura Industrial, we always work according to strict technical and regulatory criteria, ensuring the reliability of every process.

More preparation, less maintenance

Investing time and resources in proper surface preparation in industrial painting has a direct impact on coating lifespan, reduced maintenance, and the safety of structures and facilities. A well-treated substrate allows the coating system to perform under the conditions for which it was designed, maintaining its technical performance for longer.

In industrial painting, cutting corners on critical steps such as surface preparation often leads to premature repainting, unplanned downtime, and medium- to long-term cost overruns. That is why, at Mestres Pintura Industrial, we understand surface preparation not as a preliminary formality, but as the essential starting point for ensuring quality, durability, and reliability in every project.